Metal Fabrication is one of the peak businesses all over the world. Though there are lots of traders and businesses are running in this globe, the metal fabrication is the foremost business to all the companies which is happening through the large size machines and equipment which are made up of these metals. So the metal fabrication is so much complicated and also the long-time process which may be by the machines or manuals. While comparing to the manual work and the machinery work, that machinery works are the best source for this metal fabrication. People may doubt that what is mean by metal fabrication? They can be understood after reading this article which clearly explained metal fabrication. This metal fabrication is nothing but the creation of metal structures for everything this long-time process will be handled through three main steps. Machines that are made up of metal are the main work in the fabrication because all these metals are fabricated only for the machines which are the sources for a large number of factories and businesses. For these machines fabrications, the manual works and also the automation works are needed. There are three steps which exhibit the major portion of the metal fabrication.

The three stages of metal fabrications:

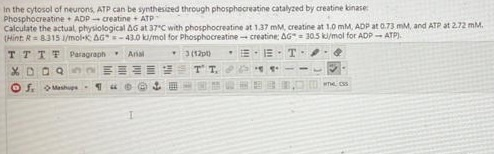

The first stage or work in this metal fabrication field is nothing but the cutting. This sound will be so heavy even though this is the first step of this metal fabrication which is the most technical and most accurate work to do. This cutting will be done by the large machines and on the other hand, it could be possibly done manuals too. The laser or plasma torches is the main tool to cut the metal as our desire and whatever the shapes people want to create at all. These are the secondary tools while comparing to the CNC machining because this kind of machining will be the most effective and also the short time work to do by the workers by a switch on the buttons which could do all the process of cutting the metals. Then the second step is joining the metals which could be possible by welding, bonding with some epoxy resin or riveting them together. For the shape which the traders have been ordered to do like, that shape should be done by the above tricks and processes. Welding is nothing but through the heat and fire or the filler material two metals are joining, then the riveting also kind of joining but through the metal-rivet. Each of these steps had its weakness and strength, so up to the process and procedure, the time will be taken for the fabrication. The third stage is bending the metal which could help to get the proper shape of the metal. Through modern machinery and also through manual work it could be possible to do unless they bend the metal, it never is used for work. The last and the final touch is nothing but the final touches of the material. In this stage, the shiner and the painting process will be happening on the metal to look like a shined one.